Photo: Finnair

Excited by the challenge, kitchen product manufacturer Fredman seized the opportunity to help the airline company Finnair in its ambitious goal of halving the use of single-use plastic in four years. Close cooperation with the Finnair Kitchen team produced an innovative cardboard meal tray concept that made it possible to reach the goal ahead of schedule.

The search for and development of substitutes for aluminum and plastic, the most common packaging materials in in-flight catering, has been ongoing worldwide for many years. Cardboard is the most viable option, but the requirements of sustainability and the use conditions present a variety of challenges.

Fredman and Finnair’s cooperation in the development of a new cardboard-based packaging solution for in-flight catering was a combination of shared ambition and agility, resulting in visionary innovation.

“The four-year goal of halving the amount of single-use plastic set at the beginning of 2018 was reached ahead of schedule, already in summer 2022 instead of at the end of that year. This was made possible, in part, by the new meal trays and their exceptionally agile product development,” says Marika Nieminen, Head of Finnair Kitchen (at the time of making this article*).

The product development of a completely new, more sustainable packaging concept came with plenty of challenges that needed solving.

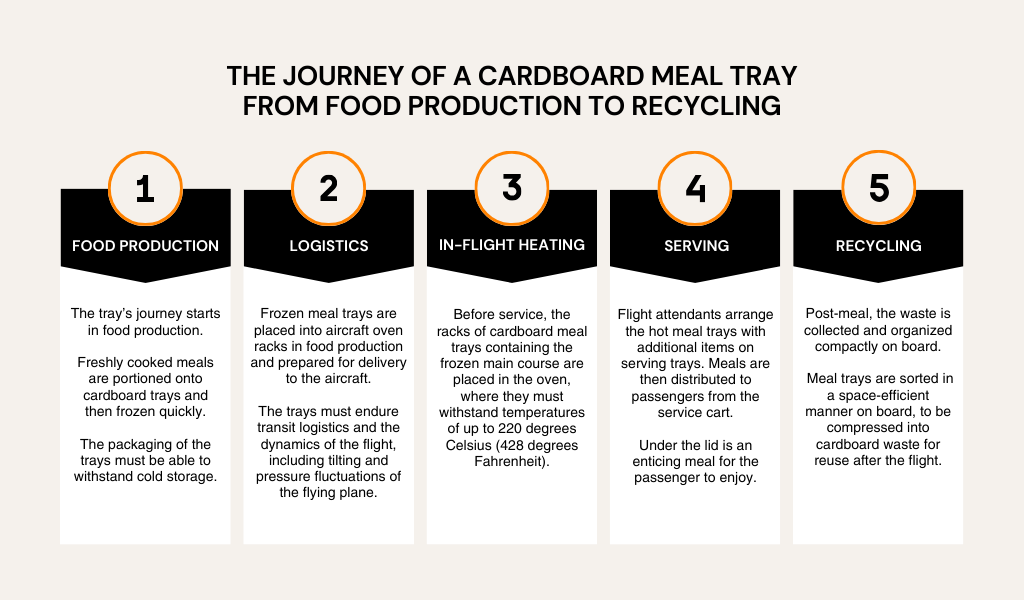

Finnair’s new meal trays had to be able to withstand all stages of the food preparation chain. From one extreme condition to the next, in a way that ensures the best food safety. With stylish and sturdy packaging, the meals must look enticing and have the right temperature when they reach the air passengers, really putting the cardboard to the test.

Fredman and Finnair first started their cooperation during the COVID-19 pandemic. At that time, Finnair Kitchen developed the Taste of Finnair ready-meal concept for grocery stores using Fredman’s Comple cardboard containers.

However, this food packaging solution did not meet the needs of aviation. No solution sufficient for Finnair’s own goals was available on the market.

“We logically continued our good cooperation with Fredman as we had a shared ambition to find a new, sustainable solution and our values coincided. Finnair’s values of working together, courage and caring were realized particularly well in the project,” Nieminen says.

According to Nieminen, Finnair Kitchen strives to source its raw materials as locally as possible. So cooperating with an operator that uses sustainable materials in its production, at a factory located in Rauma in Finland, was a natural choice. Fredman had also already convinced Finnair of the reliability of its operating chain.

The product development of the new cardboard meal tray introduced in economy class was an extensive, painstakingly executed project in which the solution was developed based on continuous testing. The Finnair personnel involved in the development work on a more concrete level were Lauri Ahonen, Finnair Kitchen’s Concept & Category Manager, and Kristos Mavrostomos, Development Manager, CX & Design.

“To succeed in a project like this, you first need the customer’s vision. It was clear: they wanted a more sustainable and environmentally friendly alternative. We set out to develop a solution based on our shared ambition. At the start, in a way, only the sky was the limit,” says Development Director Oscar Lindqvist, who was in charge of the project on the Fredman side.

The package sizes of the cardboard trays, the way the material reacts in different conditions, safe reheating temperatures and the concept’s functioning in in-flight catering were tested in test kitchen ovens simulating the safety-critical environment on board an aircraft.

Special 3D printing equipment was used to pinpoint the right tray size so that it could be optimized with the loading of ovens, the serving tray space and the dimensions of the service carts in mind, as well as to ensure optimal heat retention for the meal.

The tray is made of cardboard, with a thin PET film on the inside. This film can withstand heating to high temperatures, ensuring food safety.

En route to the final packaging concept, modifications were made based on many perspectives and operational needs. According to Lindqvist, there were plenty of prototypes.

The companies had already developed a separate cardboard box for items served cold. When it was tested with various types of dishes, the need for a coating that is more resistant to moisture and oil became obvious. With regard to the tray for hot meals, during reheating tests, the Finnair Kitchen team identified the need to adjust the size of both the portions and the actual tray. There were many variables to consider.

“The creative journey has involved some pain at times, but the team’s commitment and learning together ensured continuous development and progress. It is rewarding to see that together we have achieved something meaningful that makes an impact,” Nieminen adds, describing the nature of the project.

Finnair has stated that the amount of plastic waste generated from its operational activities was reduced by more than half during the target period.

Alongside the previously more ubiquitous plastic, the new cardboard trays used in in-flight catering also displaced a significant amount of aluminum at two points in the production chain. Moreover, the trays are lighter and more space-efficient, and the need to wash dishes has been significantly reduced. In other words, from an environmental perspective, the new alternative provides other benefits besides a reduction in the amount of single-use plastic.

According to Nieminen, it was essential that the cardboard tray was tailored to withstand the demanding conditions across the entire chain, from manufacturing to waste treatment, taking the customer and the staff experience into account at all times.

“Finnair’s sustainability efforts are continuing towards our next targets, set for 2025. Sustainable operations are rooted in our culture and are part of our day-to-day work,” Nieminen says.

At Finnair, development and results are being sought through continuous improvement, as is the case at Fredman.

The companies are currently working on a joint project to develop a lid to be integrated into the cardboard meal trays.

“As far as the overall sustainability of aviation is concerned, there is plenty of work to be done, with significant emission reductions still eluding us,” says Nieminen, continuing: “Even though reducing emissions from flying is the most important thing, Finnair wants to do as well as possible in all other areas of sustainability, too.”

A shared, value-based vision of sustainability and the need for related continuous development drive true innovation.

* In September 2024, Marika Nieminen was appointed as Vice President Inflight Experience at Finnair